When building your own RAM sticks becomes financially rational, something has gone terribly wrong with the market.

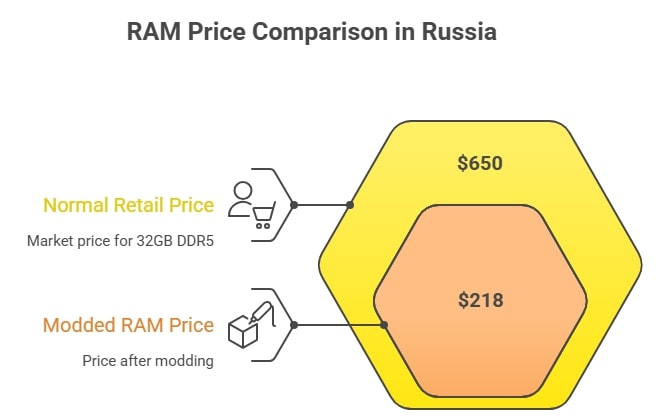

A Russian modder known as VIK-on has demonstrated what desperation and soldering skills can accomplish during the ongoing memory crisis. By harvesting chips from laptop SODIMMs and transplanting them onto desktop PCBs, he created a functional 32GB DDR5 stick for roughly $218. In Russia, where memory prices have hit particularly brutal levels, that same capacity would cost around $650 through normal retail channels.

The math works out to about a third of the market price. For a component that shouldn’t require this level of intervention, that savings margin reveals just how distorted the current situation has become.

How the mod actually works

The process starts with two 16GB DDR5 laptop SODIMMs, the smaller memory modules designed for portable machines. These serve as chip donors rather than functional components. VIK-on then sourced a compatible desktop DIMM PCB capable of accepting the harvested memory chips.

The soldering work sits firmly in advanced territory. Memory chips require precise handling, and the connections must be flawless for stable operation. Beyond the physical assembly, the mod also demanded firmware manipulation. VIK-on reportedly borrowed ADATA firmware configured with a 6400 CL32 XMP profile to get the frankenstein stick recognized and running properly.

DIY DDR5 cost comparison (Russian market):

| Option | Cost | Savings |

|---|---|---|

| Retail 32GB DDR5 | ~$650 | Baseline |

| DIY from SODIMMs | ~$218 | ~66% |

| Theoretical 8GB chip build | Lower | Packaging issues prevent viability |

The modder explored using even cheaper 8GB sticks as chip sources but ran into packaging complications that made 32GB builds impractical from that starting point. The 16GB SODIMM approach apparently hits a sweet spot between component cost and technical feasibility.

Why this matters beyond one modder’s project

This isn’t a practical guide for most people. The skills required place it well beyond casual DIY territory. Precision soldering, firmware hacking, and the patience to troubleshoot memory stability issues aren’t weekend project material.

But the existence proof matters. When someone can build functional DDR5 for a third of retail pricing, that gap represents either massive profit margins, artificial scarcity, or some combination of both. The memory market has always operated with limited competition and opaque pricing, but the current crisis has stretched those dynamics to breaking point.

The broader implications get interesting if you project forward. Should prices remain elevated long enough, the economics might eventually support commercial operations harvesting chips from lower-demand form factors and repurposing them for desktop modules. Laptop memory often trades at different price points than desktop equivalents despite using identical chips. Arbitrage opportunities exist for anyone with the technical capability to exploit them.

The skills you’d actually need

For anyone genuinely considering this path, the requirements extend beyond basic PC building knowledge.

Soldering becomes the obvious barrier. Memory chips use fine-pitch connections that demand steady hands, proper equipment, and experience with surface-mount components. A standard soldering iron won’t cut it. You’d need hot air rework stations, flux, and probably a microscope to verify connections.

Firmware handling adds another layer. Memory sticks contain SPD chips that store timing profiles, capacity information, and XMP settings. Without the right firmware, your system either won’t recognize the memory or will run it at suboptimal settings. Sourcing appropriate firmware and programming it onto your homebrew stick requires additional tools and knowledge.

Testing demands patience. Memory instability often manifests as random crashes, data corruption, or system freezes that appear unrelated to RAM. Properly validating a DIY stick means hours of stress testing to confirm stability across various workloads.

What this says about the current market

The memory crisis has created conditions where black market solutions and DIY workarounds start making economic sense. That’s not a healthy sign for an industry that should have mature supply chains and competitive pricing.

DDR5 adoption was already slower than previous generation transitions, partly due to pricing that made upgrades difficult to justify. The current shortage has compounded that problem, potentially extending the DDR4 tail longer than anyone anticipated. Builders choosing to stick with older platforms rather than pay crisis pricing represent demand that manufacturers are failing to capture.

VIK-on’s project won’t move markets or solve supply problems. But it demonstrates that the technical barriers to memory production are lower than the pricing suggests. The chips exist. The PCBs exist. The firmware exists. What’s missing is competition and capacity sufficient to meet demand at reasonable prices.

Until those fundamentals change, expect more creative solutions from modders willing to do what the market won’t.

Would you attempt a DIY memory build if prices stay elevated, or does the technical complexity make retail pricing seem reasonable by comparison?